On Saturday, September 30th the class visited the Litchfield Mine to make an evaluation of UAS platforms and GPS units for ground control. Some of the main goals of this trip were to: personally lay ground control points (GCP's), observe the difference in consumer grade and survey grade GPS devices, and weigh the pros and cons between different types of unmanned aerial system (UAS) platforms. The data collected will be later processed and analyzed, so detailed note taking throughout the day was important.

The Litchfield Mine is an aggregate mine that contains large piles of different rock, sand, and other material. This mine is regularly surveyed to determine how much material has been deposited or taken from the piles. Unmanned aerial systems (drones) can be used as a method of surveying the mine to measure the sizes of each pile of material. This is done by laying ground control points and noting the exact location of each using GPS. The imagery taken throughout the flight path of the drone is then brought into a GIS and the imagery is laid down onto a map by pinpointing the exact location of each of those GCP's. This is also known as georeferencing. This is a relatively new form of technology so the entire surveying industry does not rely on UAS, but this emerging surveying method shows promising efficiency.

UAS professionals from the surveying industry were invited by Professor Joseph Hupy to give demonstrations using their survey grade UAS platforms and other surveying technology. Professionals from Topcon Solutions and Menet Aero came to work with us in the field. They provided some cutting edge drones as well as a wealth of knowledge about the industry and new technology.

The study area is shown in Figure 1.

|

| Figure 1: This map shows the location of the Litchfield Mine, near Eau Claire, Wisconsin. |

Methods

The first step we took in surveying the mine was laying down ground control points. The class laid 16 GCP's throughout the mine. Each GCP is about a 2' x 2' colored square marker with a center point from which to measure the exact GPS location. The more GCP's used in a survey the more accurate the survey can be when it is georeferenced later. They must also be spread wisely throughout the mine. If some GCP's are too bunched together it can create warping of the imagery when being georeferenced. The location of all the GCP's were noted in a rough drawing in a field notebook so that none of them were lost in the process.

Once all the GCP's were set we measured the GPS location using three different devices: the Topcon HiPer, the Bad Elf GPS, and an iphone. This is shown in Figure 2. The Bad Elf and iphone locations were recorded by the students, and the Topcon HiPer units were recorded by the professionals. The professionals from Menet Aero also laid down Arrow GPS markers to make some extra GCP's, as seen in Figure 3. Each marker is solar powered and waterproof, and they record their GPS location with the press of a button.

|

| Figure 2: This picture shows GCP #8. Peter from Menet Aero records the location with the Trimble R2, while my group members record the locations from the Bad Elf and the iphone. |

The Topcon HiPer was also used to record the location of each of the 16 GCP's. This device is very similar to the Trimble R2, as seen in Figure 4. The Topcon HiPer runs off a screen device that records the longitude, latitude, and elevation. The data collected from the day will be used to compare the accuracy of the locations from each device so they too can be compared to each other when the data is analyzed.

|

| Figure 4: This picture shows the Trimble R2 (yellow) alongside the Topcon HiPer (red). |

Next the UAS platforms were flown to survey the mine, and Josh Nave from Topcon also showed us a stationary device used to survey individual piles (Topcon Robotic Total Station). The professionals from Topcon Solutions and Menet Aero informed us of the pros and cons of each device, as well as cost and other important details.

|

| Figure 5: PJ from Menet Aero flies the Phantom 3. |

|

| Figure 6: This image shows the handheld controller with a screen that is used to control the Phantom 3. |

|

| Figure 7: Here Josh from Topcon Solutions prepares the Ebee Plus for flight. |

|

| Figure 8: Peter Menet flies the M600 Pro with Zenmuse X5. This one is more expensive and powerful so the launching/landing area must be coned off. |

|

| Figure 9: Peter Menet prepares the C-Astral Bramor w/ Sony a6000 for flight. |

|

| Figure 10: Josh Nave from Topcon Solutions shows how the Topcon Robotic Total Station is used to measure/model a gravel pile. |

Results

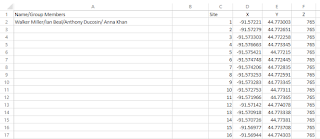

|

| Figure : This is the excel spreadsheet that includes the data collected from the iphone for our group, with the z coordinate being the elevation unit. |

Conclusion

This fieldwork proved to be a valuable experience in learning about UAS platforms and surveying with this cutting edge technology. The professionals from Topcon Solutions and Menet Aero were good resources in providing us with background information about each of their devices, as well as informing us about the surveying industry. This technology may begin to become the main way in which volumetrics is modeled and measured in the surveying industry.

The fixed wing drones may be more expensive and seem more reliable than the rotary wing drones, but after observing the two fixed wing drones crash it seems that the rotary wing drones may be more reliable in similar conditions to what we had on Saturday. It should also be noted that insurance for these drones is very important. The total number of dollars in equipment used throughout the day was up to a couple hundred thousand dollars, so having insurance on this equipment is vital just in case accidents do happen.

We were able to conclude that the GPS in smart phones is much less accurate than the Bad Elf, and the data that will be processed later will probably reveal that it is far less accurate than the survey grade GPS devices.

No comments:

Post a Comment